Dear shareholders!

In 2010 Mosenergo succeeded in reliably and uninterruptedly providing electric energy and heat to industries and general public.

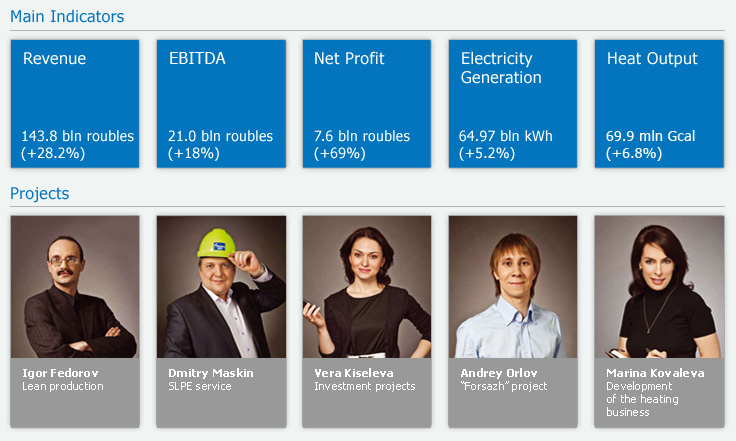

Over the year, the financial performance of the Company has improved substantially. Thus, EBITDA increased by 17% compared to 2009 and amounted to 21 billion roubles whereas net profit reached the record level of 7.6 billion roubles, which is 69% over the net profit of the previous year.

In December 2010, Dividend policy of Mosenergo was approved by the decision of the Board of Directors. The established procedure of calculation of the amount of dividends allows paying 5% to 35 % of the net profit of the company as dividends under the condition that the reserve fund is fully created as according to the Articles of Association.

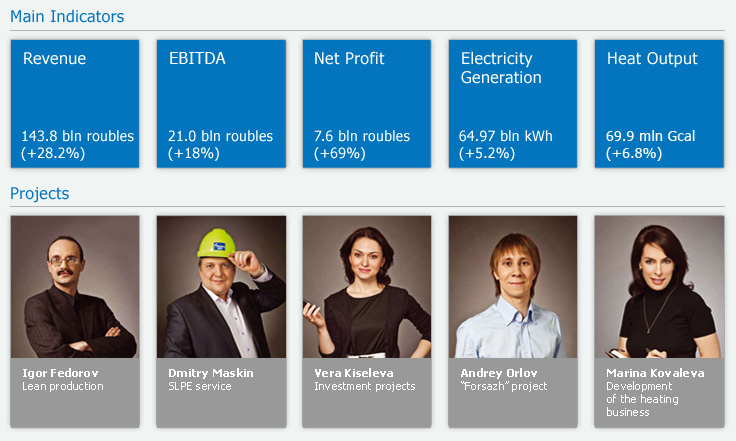

In 2010 we successfully fulfilled all the tasks for the year, the most important of which was the implementation and further dissemination of the “Lean production” program at the plants operated by Mosenergo and in the General Directorate.

The principal objectives of the Program were to increase reliability of equipment operation and to minimize the production expenses of the Company. The tools and procedures being implemented at the affiliates of the company are designed to eliminate all the possible kinds of production losses and to increase overall efficiency of operation.

The integrated program of lean production is presently in place at the thermal power plants TPP-23, TPP-21, TPP-11, and TPP-25. Implementation is in progress at TPP-8, TPP-20, TPP-27, TPP-12, and TPP-22. Overall economic effect of implementation of the “Lean production” program at four affiliates of Mosenergo in 2010 amounted to 344.4 million roubles.

The ongoing transformations significantly affected operation of power plants. Major initiatives are intended for enhancing reliability of equipment operation and minimizing fuel consumption. Equipment reliability can be increased by means of standardization of equipment walkdown programs and implementation of tools and instrumentation for visualization and accounting of defects. Fuel consumption can be decreased at the expense of minimization of the deviations of the key technical and economic parameters from the prescribed values, standardization of the choice of auxiliary equipment, control of in-house power consumption. More attention is also being given to decreasing deviations of the operating modes from the dispatcher schedules with the aid of tools standardizing personnel actions. Overall economic effect from the optimization of operations in 2010 amounted to 2010.

In the framework of development of continuous improvement system, an innovation Committee was established in the General Directorate with the participation of the representatives of technical services and investment department. A set of meeting was organized at the affiliates to generate ideas for improvement; united electronic database of improvement ideas started functioning. 480 measures were suggested in 2010 with the overall economic effect of 250 million roubles. Some of these measures are under implementation at the moment.

Implementation of the program of measures in the area of labor and environment protection.

In order to strengthen labor and employee health protection and minimize the risk of accidents, a service for safety, labor protection and ecology independent of the technical service and plant directors and reporting directly to the CEO was established.

In 2010, analysis of risks was performed and strategic program of labor protection activities for 2011-2014 was produced. Most of the measures from the “30 Program” – a program of simple visible initiatives aimed to enhance labor protection – have been implemented. Thus, standard section about penalties for violation of labor protection routines was introduced into contractual agreements with contractor organizations.

In order to enhance motivation and involve the managerial, administrative and technical personnel into labor protection and accident prevention activities, the safety, labor protection and environmental unit introduced a quarterly in-depth audit of all the power plants of Mosenergo by mobile brigades of the labor protection and fire safety service of the general directorate rating the plant performance as a result of such audits.

Operating personnel of the affiliates was trained in six standard operational procedures, which decreased the risks associated with human performance in case of abnormal situations.

“Labor protection days” are held at the affiliates of Mosenergo on a monthly basis, weekly information leaflets of the safety, labor protection and environmental unit are circulated to all the plants, display stands with visual information about occupational injures are installed at all the plants.

Expense optimization and monitoring

In 2010, a series of expense optimization and monitoring activities were performed in the Company. Despite the 37% increase of expenses for fuel (mostly caused by substantial increase of fuel prices), the rate of growth of prime cost in 2010 did not exceed the rate of growth of revenues.

Increase of the recurring expenses by 9% without amortization and depreciation is on the whole consistent with the 2010 inflation rate (8.8%). This growth was mostly due to one-time events. The main share in the structure of recurring expenses belonged to labor remunerations (+3.7%), which according to the accounting standards included one-time payments of severance benefits and other expenses for personnel in relation to liquidation of non-production affiliates and organizations. Exclusive of these non-recurring payments, labor remuneration expenses decreased by 3.3%.

Maintenance activities were continued to be contracted out in 2010. Specifically, the Central Mechanical Maintenance Plant consolidated earlier was separated from Mosenergo.

Besides that, other important projects were initiated and being developed in the Company in order to further increase effectiveness of its operation: extension of usage and addition of new SAP software modules, development of heating business of the Company, continued design and construction of new generating capacities under Capacity Supply Agreements.

All these areas will remain among the priorities for 2011.

V.G. Yakovlev

Director General of Mosenergo